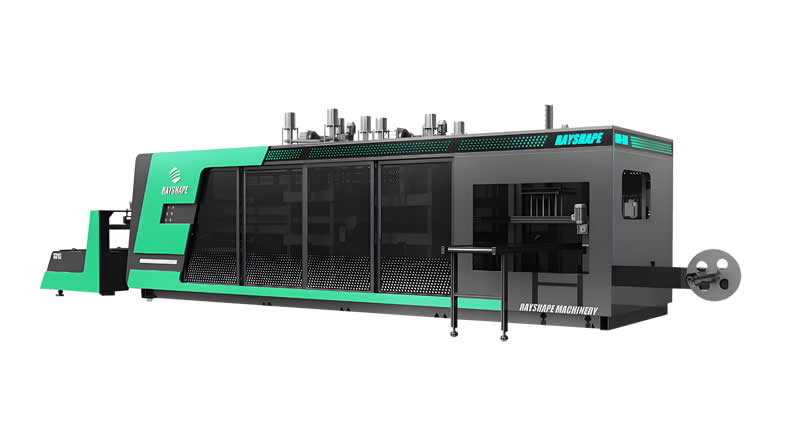

Plastic Thermoforming Machine

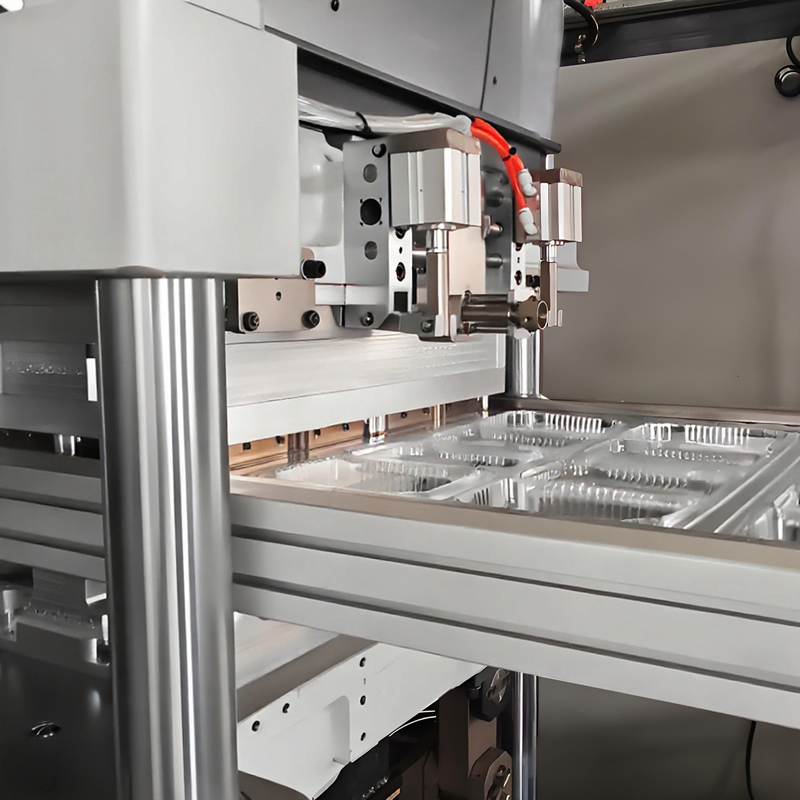

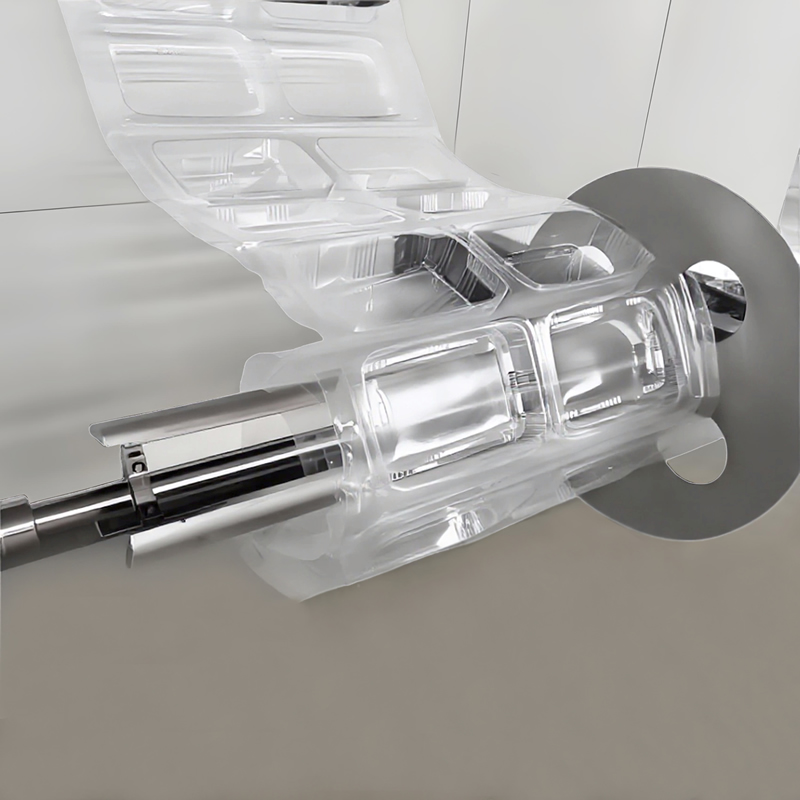

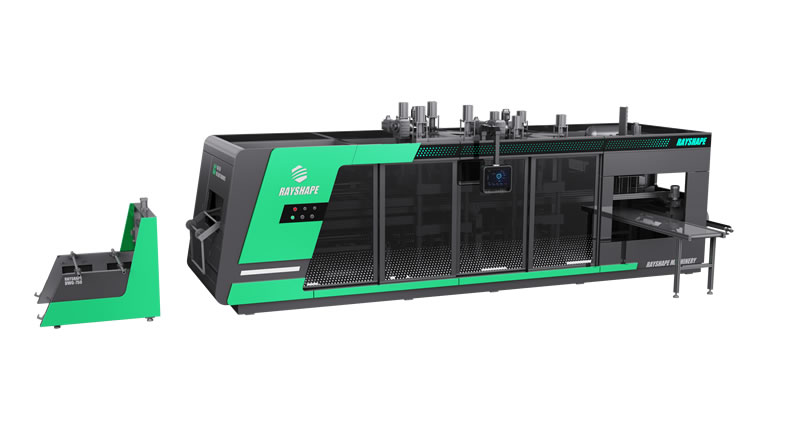

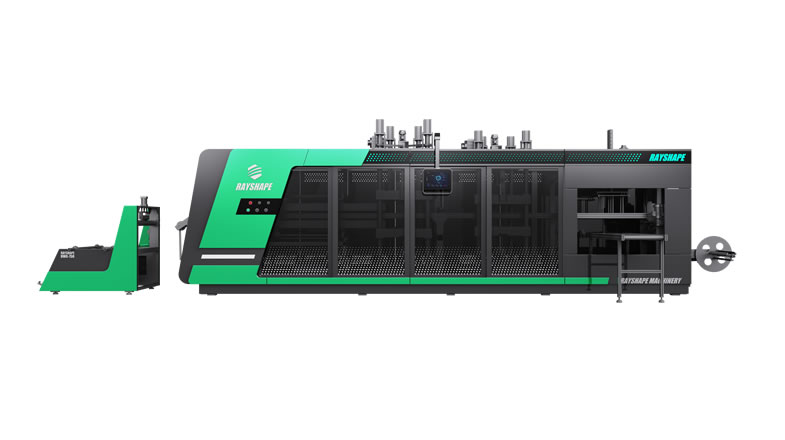

The Plastic Thermoforming Machine, often recognized as a multi-station thermoforming machine, represents a significant leap forward in manufacturing technology. Developed specifically to address the challenges of high-volume, low-consumption production, this equipment is engineered to reduce labor costs and ensure stable, reliable output. These highly automated systems are typically available in three-station and four-station configurations, with the four-station model featuring an integrated punching station for enhanced efficiency. These machines are essential for manufacturing a wide range of disposable items, including egg trays, plastic meal boxes, cup lids, and fruit packaging boxes.

Rayshape offers thermoforming machines with versatile forming plate surfaces, available in three standard sizes: 650 * 450 , 730 * 610 , 730 * 800 . The capacity of the equipment is directly correlated to the plate size; larger plates accommodate more mold cavities, leading to higher overall production output.

Our machines demonstrate impressive speed and material flexibility, suitable for processing materials such as PP, PET, and PS. When running PET sheets, the maximum operating speed can reach up to 45 molds per minute. For PP sheets, the maximum speed is typically up to 30 molds per minute. It is important to note that actual operating speed is influenced by product depth and sheet thickness; deeper products inherently require a longer forming time.

Built on a brand-new design concept and a future-oriented control system, this machine guarantees operational excellence. Recognizing that each mold set requires unique operating parameters, we have integrated a parameter save function within the equipment program. Once an engineer successfully debugs and optimizes a mold in the factory, the specific parameters are permanently saved. Subsequently, resuming production with that same mold is as simple as clicking 'start,' and the machine will automatically execute the previously stored settings.

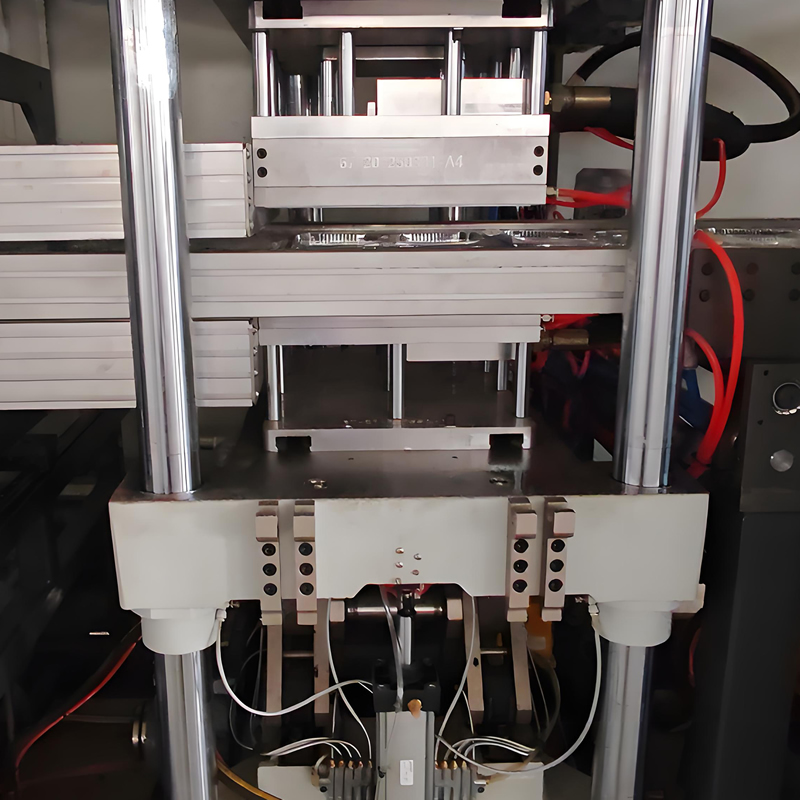

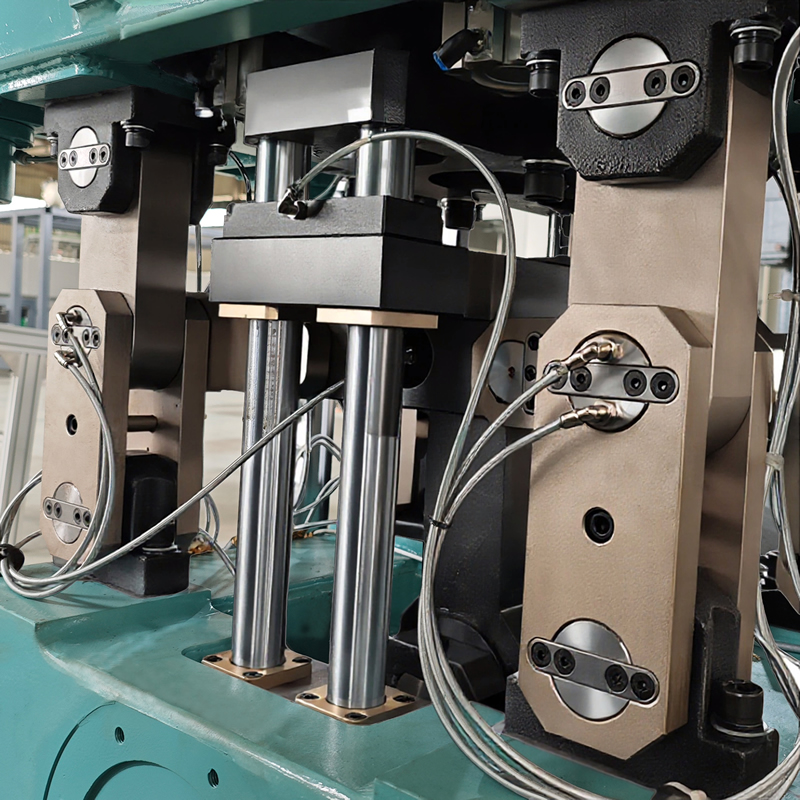

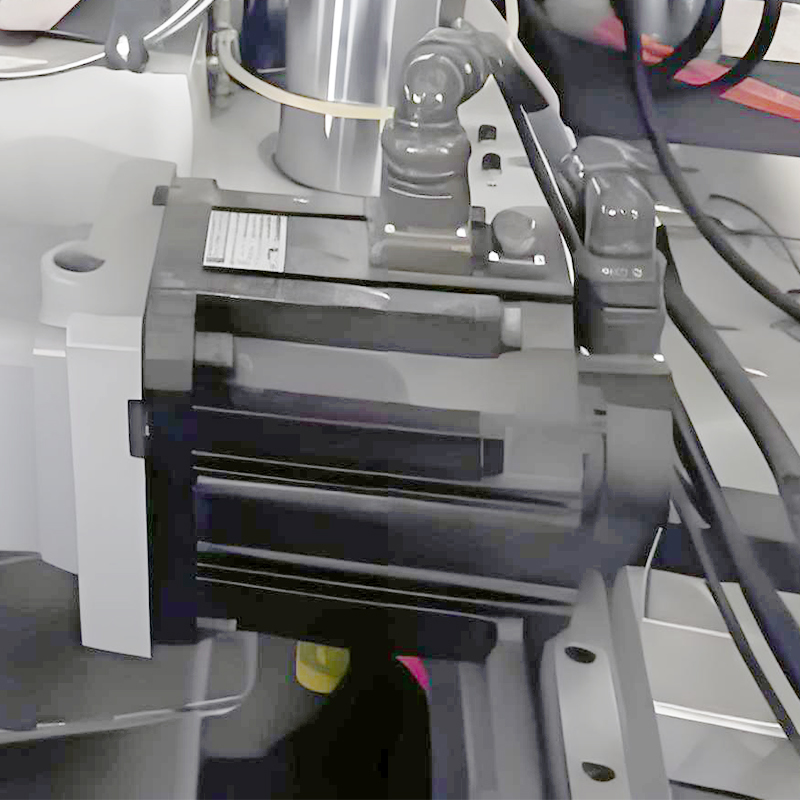

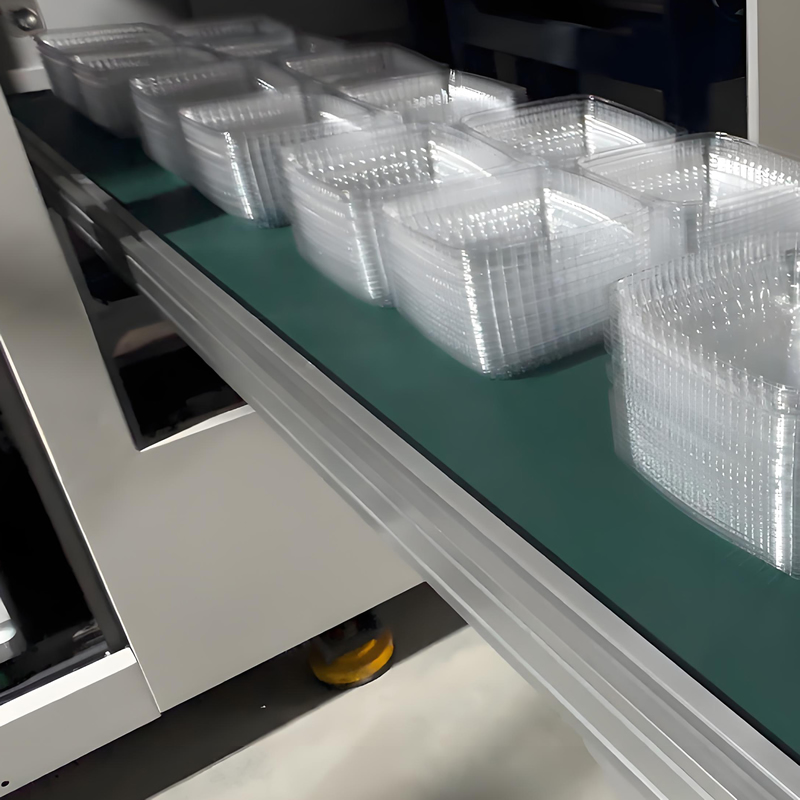

Images of Plastic Thermoforming Machines

About Rayshape

Wenzhou Rayshape Machinery Co., Ltd. is a key subsidiary of the Elemotion Group, a young and dynamic company committed to becoming a leader in the domestic packaging machinery industry, boasting a team of over 700 people and cumulative sales of nearly 20,000 packaging machines.

Rayshape is strategically located at No. 19, East Section of Pinghai Avenue, Binhai New Area, in the beautiful coastal city of Pingyang County, Wenzhou, Zhejiang Province. We operate as a comprehensive manufacturing enterprise that integrates mechanical and software R&D, production, marketing, and robust after-sales service.

Our current structure is the result of strategic growth: in 2021, Elemotion invested in Wuhu Youhe Automation Technology Co., Ltd., which was officially renamed Wenzhou Rayshape Machinery Co., Ltd. in 2025 and is now wholly owned by Wenzhou Elemotion Holdings. This strong corporate backing is part of Elemotion's expansive footprint, which includes two physical factories covering 210000 m² in Wuhu and Wenzhou, and branch offices serving over 7,000 companies across more than a dozen major cities in China.

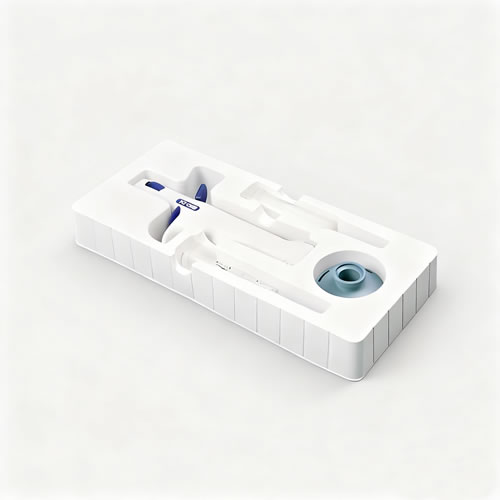

Wenzhou Rayshape Machinery Co., Ltd. boasts a seasoned R&D team, strong operational capabilities, and a solid financial foundation. We are dedicated to the development and production of high-end, energy-efficient, and highly automated equipment, including positive and negative pressure plastic thermoforming machines, plastic sheet extrusion lines, and plastic roll forming machines. These machines are compatible with a wide range of materials such as A-PET, R-PET, BOPS, HIPS, PP, PLA, and PVC, enabling the production of various plastic finished products. Carrying forward Elemotion's spirit of diligence and continuous improvement, we constantly strive for self-surpassing excellence, embracing innovation to develop high-quality automated equipment and committed to learning from Elemotion's path toward becoming a leading enterprise in the industry.

PDF Download

PDF Download