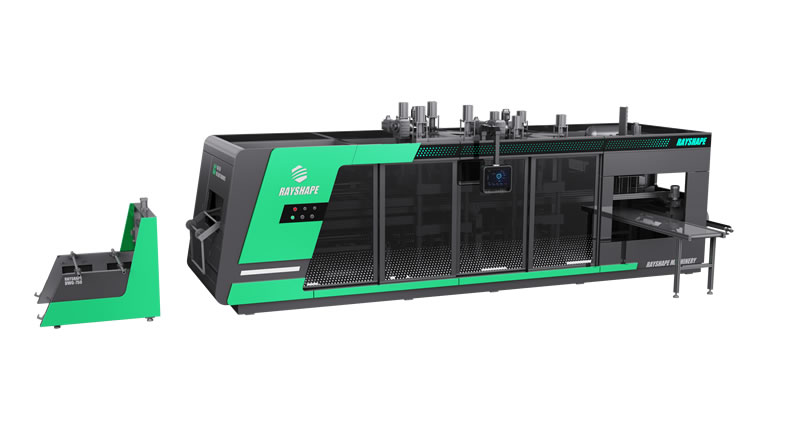

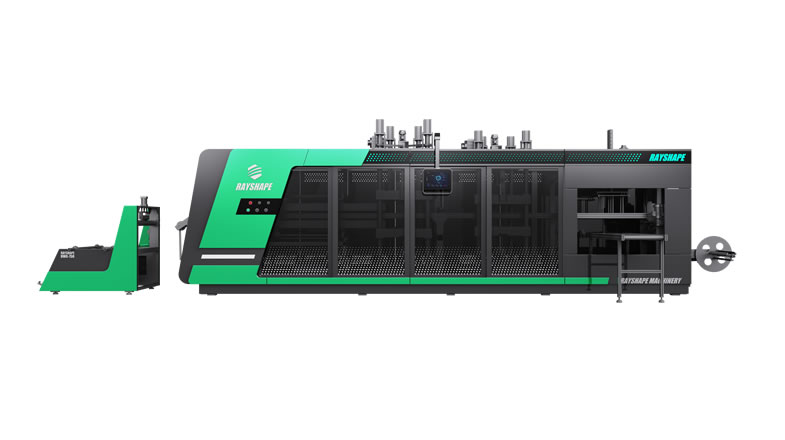

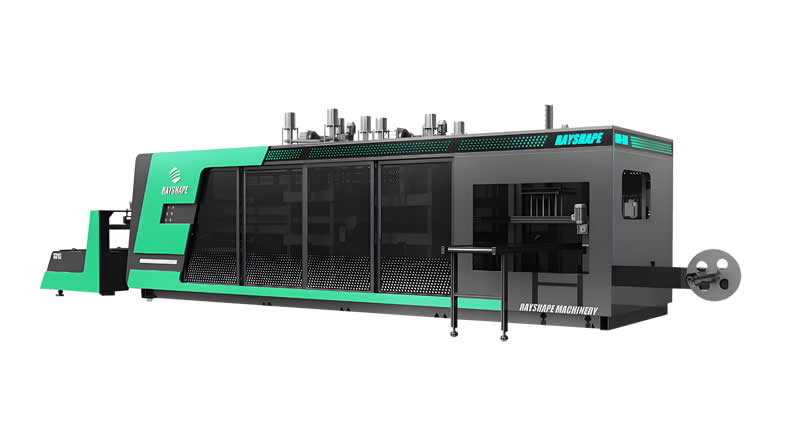

Plastic Thermoforming Machine

Plastic Thermoforming Machine - three station

Fully Automatic Plastic Thermoforming Machine

Plastic Thermoforming Equipment

RAYSHAPE Plastic Thermoforming Machine

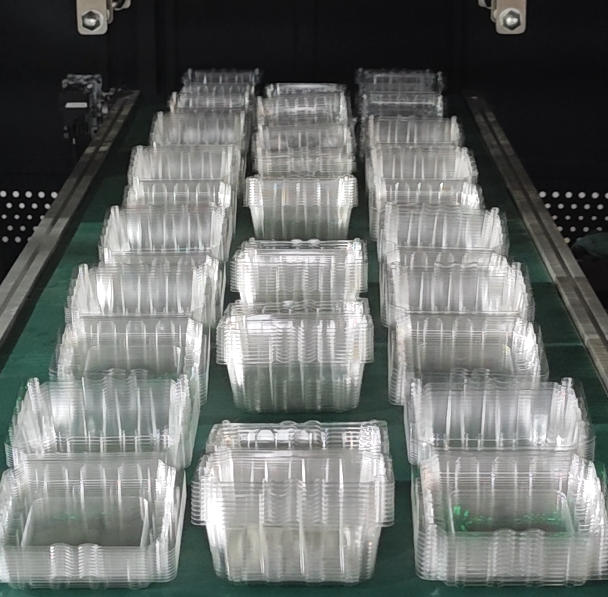

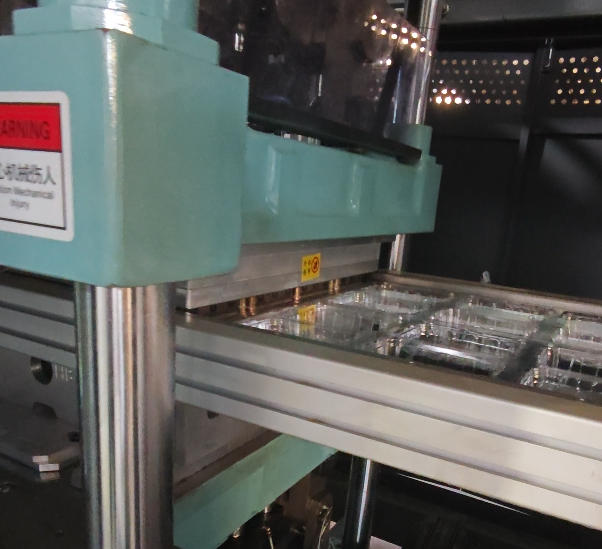

Rayshape offers thermoforming machines with versatile forming plate surfaces, available in three standard sizes: 650 * 450 , 730 * 610 , 730 * 800 . The capacity of the equipment is directly correlated to the plate size; larger plates accommodate more mold cavities, leading to higher overall production output.

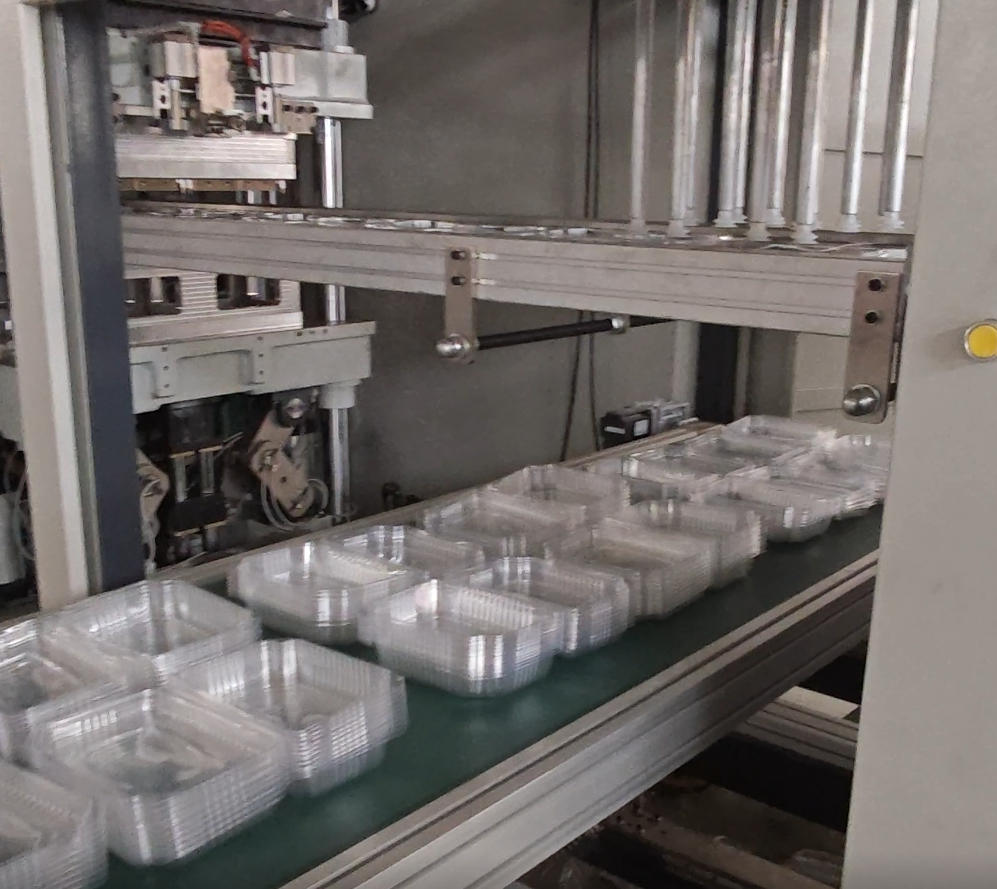

Our machines demonstrate impressive speed and material flexibility, suitable for processing materials such as PP, PET, and PS. When running PET sheets, the maximum operating speed can reach up to 45 molds per minute. For PP sheets, the maximum speed is typically up to 30 molds per minute. It is important to note that actual operating speed is influenced by product depth and sheet thickness; deeper products inherently require a longer forming time.

Built on a brand-new design concept and a future-oriented control system, this machine guarantees operational excellence. Recognizing that each mold set requires unique operating parameters, we have integrated a parameter save function within the equipment program. Once an engineer successfully debugs and optimizes a mold in the factory, the specific parameters are permanently saved. Subsequently, resuming production with that same mold is as simple as clicking 'start,' and the machine will automatically execute the previously stored settings.

Plastic Thermoforming Machine Video

Plastic Thermoforming Machine News

Engineering Precision: Understanding the Mechanics of Rayshape Multi-station Thermoforming Machines

Introduction Precision engineering is the backbone of the plastic packaging industry. To produce a perfect Fruit box making machine output or a high-quality Cup Making Machine product, every millim...

The Green Revolution in Plastic Packaging: Material Versatility and Sustainability with Rayshape Machinery

The Global Shift in Packaging Dynamics The global packaging industry is undergoing a monumental shift. With increasing environmental regulations and a growing consumer preference for sustainable op...

Precision in Food Packaging: How Rayshape’s Multi-Station Systems Define the Future of Disposable Containers

Meeting the Rigorous Standards of the Food Industry In the food packaging sector, hygiene, consistency, and speed are the three pillars of success. Whether it is an Egg tray making machine ap...

The Digital Transformation of Thermoforming: Why Rayshape Control System is a Manufacturer Greatest Asset

The Evolution from Mechanical to Digital Intelligence The era of the "manual" factory is over. In today’s competitive landscape, the difference between profit and loss often comes down to how quick...

The Revolution of Automation in Modern Packaging: A Deep Dive into Rayshape Machinery’s Fully Automatic Thermoforming Solutions

Introduction In the rapidly evolving landscape of global manufacturing, the demand for efficiency, precision, and cost-effectiveness has never been higher. As industries shift toward sustainable an...

From Sheet to Shelf: The Integrated Production Power of Plastic Sheet Extruders and Thermoforming Lines

Introduction In the competitive world of disposable container manufacturing, vertical integration is the key to maximizing profit margins. Rayshape Machinery provides a comprehensive ecosystem that...