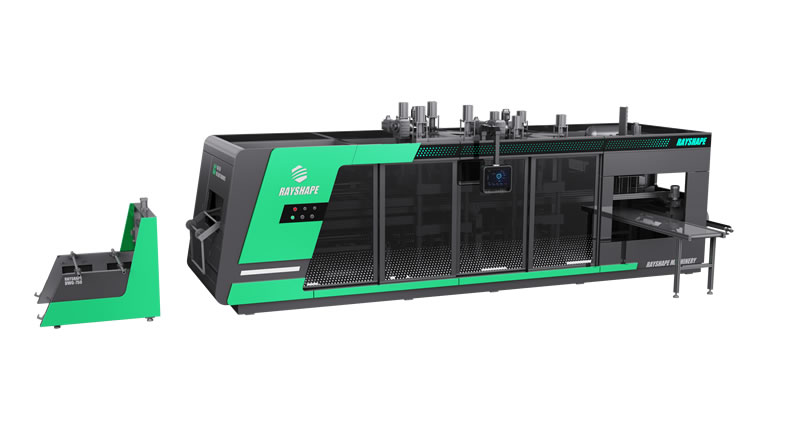

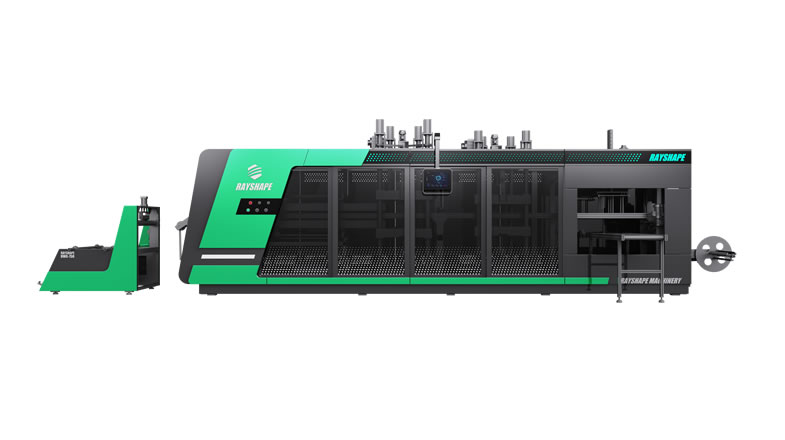

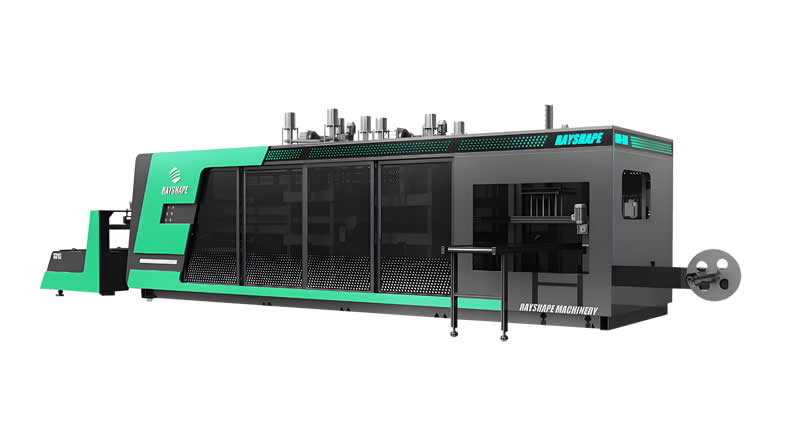

Plastic Thermoforming Machine

Plastic Thermoforming Machine - three station

Fully Automatic Plastic Thermoforming Machine

Plastic Thermoforming Equipment

The Digital Transformation of Thermoforming: Why Rayshape Control System is a Manufacturer Greatest Asset

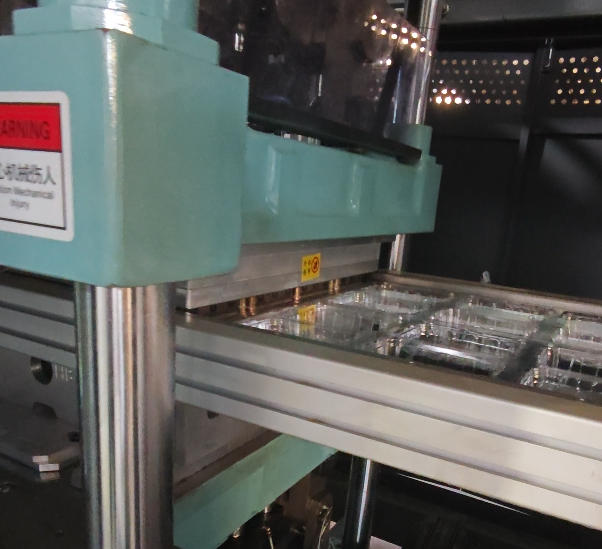

The Evolution from Mechanical to Digital Intelligence The era of the "manual" factory is over. In today’s competitive landscape, the difference between profit and loss often comes down to how quickly a machine can be set up and how consistently it can run. At Rayshape Machinery, we recognized early on that the future of the Plastic Thermoforming Machine lay not just in its steel and heaters, but in its "brain." Our latest generation of Fully Automatic Thermoforming Machines is powered by a future-oriented control system that simplifies complex engineering into a user-friendly interface.

The "Start-and-Go" Philosophy: Parameter Save Function One of the most significant barriers to high-volume production is the "debugging" phase. Traditionally, when a new mold—such as one for a Cup Making Machine or a Bowl Making Machine—was installed, a senior engineer would spend hours or even days adjusting temperatures, pressure timings, and motor speeds. This downtime is costly.

Rayshape has eliminated this bottleneck with our integrated parameter save function. When a mold is first set up at our factory or on the client's floor, our engineers optimize every variable for that specific product. These settings are then permanently saved within the machine's program. For future production runs, the operator simply needs to call up the specific mold profile and click "start." The machine automatically executes the stored settings, ensuring that the first product off the line is just as perfect as the last. This removes the reliance on highly specialized labor and ensures a stable, reliable output regardless of who is operating the machine.

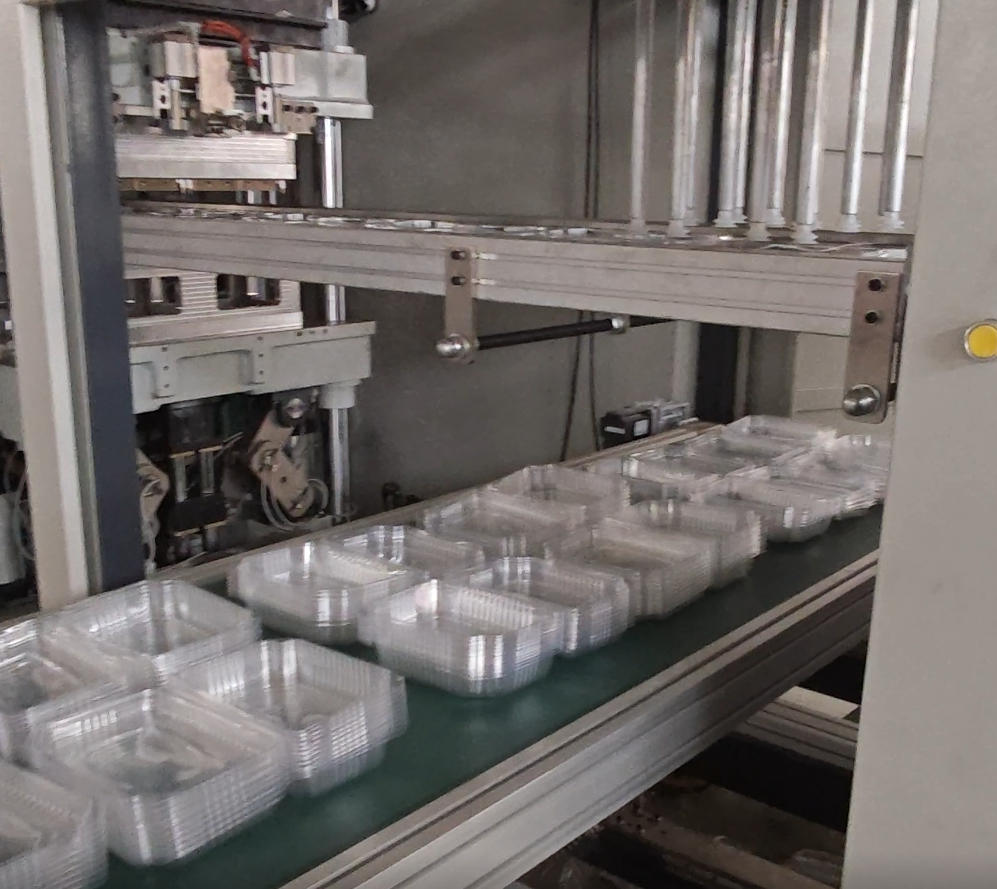

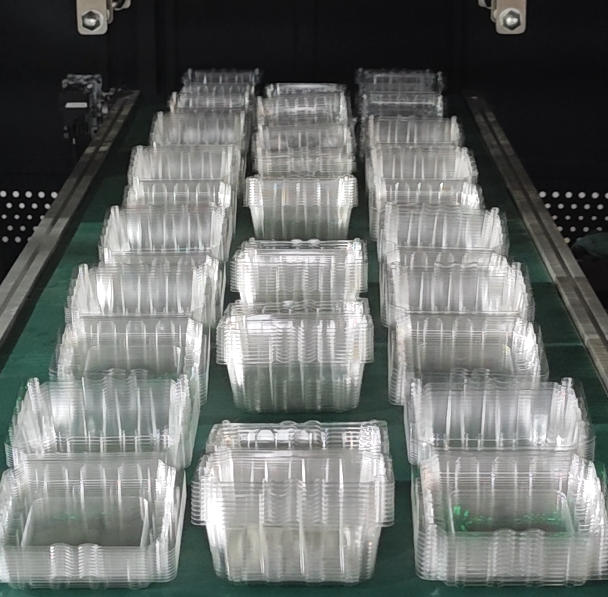

Dynamic Speed Control and High-Speed Performance Our control system does more than just remember settings; it actively manages the machine's performance in real-time. We understand that actual operating speed is a delicate balance influenced by product depth and sheet thickness. For example, a shallow tray on a Plastic Thermoforming Machine can run at maximum speeds, whereas a deep-drawn fruit box requires a longer forming time to ensure wall thickness consistency.

Our system monitors these variables, allowing for PET production at up to 45 molds per minute and PP at 30 molds per minute. This intelligent monitoring prevents common issues like "webbing" or "thinning," which often plague lower-end machines. By providing this level of digital oversight, Rayshape ensures that our Multi-station Thermoforming Machine delivers a level of consistency that is required for high-speed automated filling lines.

Vertical Integration: From Extruder to Finished Product To achieve total control over the production process, many of our clients pair our forming machines with a Rayshape Plastic Sheet Extruder. Our control systems can be integrated to allow for a holistic view of the production line. This vertical integration allows for real-time adjustments to the sheet thickness at the extruder based on the forming results at the thermoformer. This creates a smart factory environment where data flows between machines to minimize waste and maximize efficiency.

A Legacy of Innovation: Rayshape and Elemotion Wenzhou Rayshape Machinery Co., Ltd., as a subsidiary of the Elemotion Group, is committed to the path of self-surpassing excellence. Our transition from Wuhu Youhe Automation to the fully-fledged Rayshape brand in 2025 represents our commitment to the high-end market. Based in Wenzhou, Zhejiang, we leverage a seasoned R&D team to push the boundaries of what a Blister Machine or a Fruit box making machine can do. We are dedicated to learning from Elemotion’s history while forging our own path as a leading enterprise in the global plastic machinery industry.

Plastic Thermoforming Machine Video

Plastic Thermoforming Machine News

Engineering Precision: Understanding the Mechanics of Rayshape Multi-station Thermoforming Machines

Introduction Precision engineering is the backbone of the plastic packaging industry. To produce a perfect Fruit box making machine output or a high-quality Cup Making Machine product, every millim...

The Green Revolution in Plastic Packaging: Material Versatility and Sustainability with Rayshape Machinery

The Global Shift in Packaging Dynamics The global packaging industry is undergoing a monumental shift. With increasing environmental regulations and a growing consumer preference for sustainable op...

Precision in Food Packaging: How Rayshape’s Multi-Station Systems Define the Future of Disposable Containers

Meeting the Rigorous Standards of the Food Industry In the food packaging sector, hygiene, consistency, and speed are the three pillars of success. Whether it is an Egg tray making machine ap...

RAYSHAPE Plastic Thermoforming Machine

The Plastic Thermoforming Machine, often recognized as a multi-station thermoforming machine, represents a significant leap forward in manufacturing technology. Developed specifically to address the c...

The Revolution of Automation in Modern Packaging: A Deep Dive into Rayshape Machinery’s Fully Automatic Thermoforming Solutions

Introduction In the rapidly evolving landscape of global manufacturing, the demand for efficiency, precision, and cost-effectiveness has never been higher. As industries shift toward sustainable an...

From Sheet to Shelf: The Integrated Production Power of Plastic Sheet Extruders and Thermoforming Lines

Introduction In the competitive world of disposable container manufacturing, vertical integration is the key to maximizing profit margins. Rayshape Machinery provides a comprehensive ecosystem that...