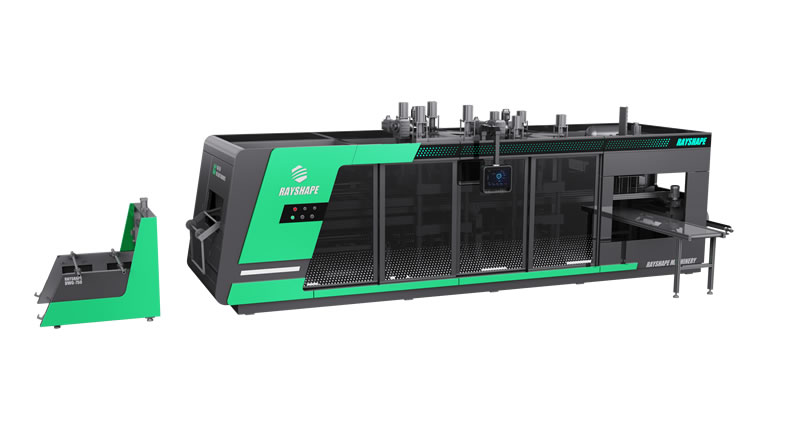

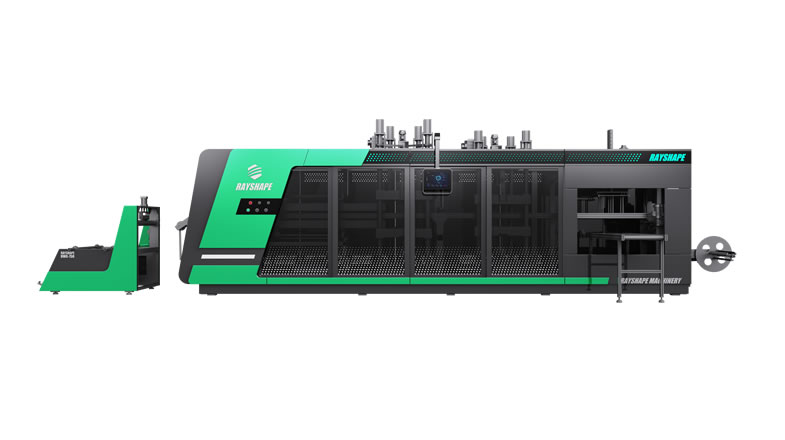

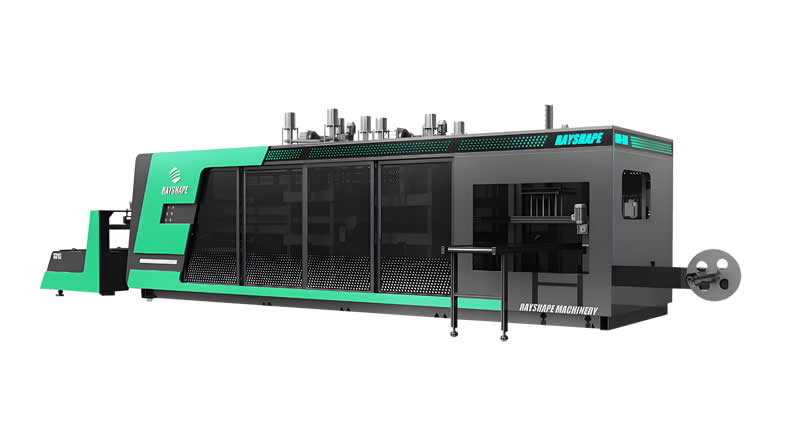

Plastic Thermoforming Machine

Plastic Thermoforming Machine - three station

Fully Automatic Plastic Thermoforming Machine

Plastic Thermoforming Equipment

The Green Revolution in Plastic Packaging: Material Versatility and Sustainability with Rayshape Machinery

The Global Shift in Packaging Dynamics The global packaging industry is undergoing a monumental shift. With increasing environmental regulations and a growing consumer preference for sustainable options, manufacturers are under immense pressure to transition toward eco-friendly materials such as PLA (Polylactic Acid) and R-PET (Recycled Polyethylene Terephthalate). However, processing these materials requires more than just a standard machine; it requires the high-precision, stable thermal control found in Rayshape Machinery’s advanced equipment. As a leading Plastic Thermoforming Machine manufacturer, Rayshape is at the forefront of this "Green Revolution," providing the technology necessary to turn sustainable resins into high-quality consumer products.

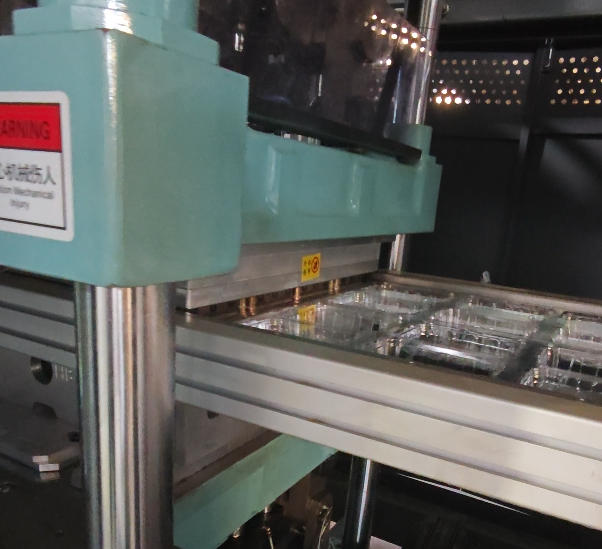

Engineering for Material Diversity One of the core strengths of Wenzhou Rayshape Machinery Co., Ltd. is our equipment's compatibility with a vast array of polymers. While traditional machines might struggle with the narrow processing windows of bio-plastics, our Fully Automatic Thermoforming Machine is engineered to handle A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, and even PVC. This versatility is essential for modern factories that must pivot between different production runs to satisfy diverse client demands.

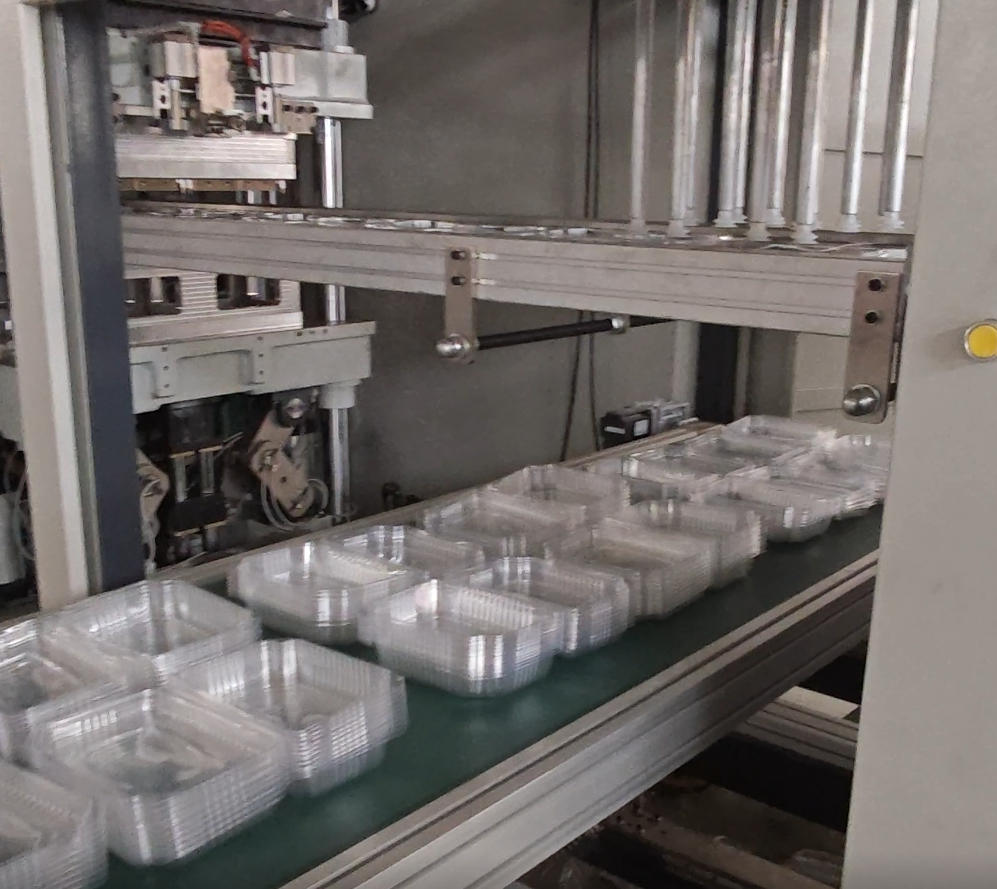

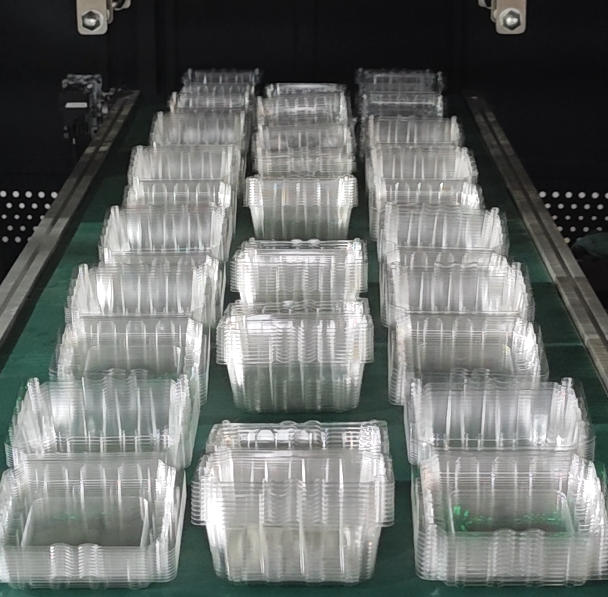

For instance, processing PET requires rapid cooling and high-speed cycles. Our machines are capable of reaching a staggering 45 molds per minute when running PET sheets. In contrast, PP (Polypropylene) requires a different thermal profile due to its crystalline structure and shrinkage rates. Even so, Rayshape’s technology maintains a robust speed of up to 30 molds per minute for PP. The ability to switch between these materials without extensive hardware overhauls is what makes our Multi-station Thermoforming Machine a critical asset for any forward-thinking enterprise.

The Role of the Plastic Sheet Extruder in Sustainable Cycles Sustainability starts with the raw material. Rayshape’s Plastic Sheet Extruder is the first step in creating a closed-loop manufacturing process. By utilizing our extrusion lines, manufacturers can precisely control the blend of virgin and recycled content. Our extruders are designed to produce sheets with high transparency and uniform thickness, which are prerequisite conditions for high-quality thermoforming. When the extrusion line is synced with a Fruit box making machine or a Bowl Making Machine, the result is a seamless, energy-efficient production cycle that minimizes waste and maximizes resource utility.

Overcoming the Challenges of Eco-Friendly Polymers PLA and other biodegradable materials are notorious for their temperature sensitivity. If the heat is too low, the material won't form; if it's too high, it degrades. Rayshape has addressed this through a brand-new design concept and a future-oriented control system. Our machines feature multi-zone infrared heating panels that allow for granular control over every square centimeter of the plastic sheet. This ensures that even the most temperamental materials are heated to their optimal forming temperature, resulting in products with superior clarity and structural integrity.

Corporate Vision: A Subsidiary of Elemotion Group Rayshape Machinery, located in the Binhai New Area of Pingyang County, Wenzhou, carries the DNA of the Elemotion Group. Since our rebranding and total acquisition by Wenzhou Elemotion Holdings in 2025, we have focused on high-end, energy-efficient automation. Our R&D team doesn't just look at the mechanical output; they look at the environmental footprint. By reducing energy consumption and enabling the use of recycled materials, Rayshape is helping the packaging industry move toward a more sustainable future while maintaining the high-speed profitability that our clients expect.

Plastic Thermoforming Machine Video

Plastic Thermoforming Machine News

Engineering Precision: Understanding the Mechanics of Rayshape Multi-station Thermoforming Machines

Introduction Precision engineering is the backbone of the plastic packaging industry. To produce a perfect Fruit box making machine output or a high-quality Cup Making Machine product, every millim...

Precision in Food Packaging: How Rayshape’s Multi-Station Systems Define the Future of Disposable Containers

Meeting the Rigorous Standards of the Food Industry In the food packaging sector, hygiene, consistency, and speed are the three pillars of success. Whether it is an Egg tray making machine ap...

The Digital Transformation of Thermoforming: Why Rayshape Control System is a Manufacturer Greatest Asset

The Evolution from Mechanical to Digital Intelligence The era of the "manual" factory is over. In today’s competitive landscape, the difference between profit and loss often comes down to how quick...

RAYSHAPE Plastic Thermoforming Machine

The Plastic Thermoforming Machine, often recognized as a multi-station thermoforming machine, represents a significant leap forward in manufacturing technology. Developed specifically to address the c...

The Revolution of Automation in Modern Packaging: A Deep Dive into Rayshape Machinery’s Fully Automatic Thermoforming Solutions

Introduction In the rapidly evolving landscape of global manufacturing, the demand for efficiency, precision, and cost-effectiveness has never been higher. As industries shift toward sustainable an...

From Sheet to Shelf: The Integrated Production Power of Plastic Sheet Extruders and Thermoforming Lines

Introduction In the competitive world of disposable container manufacturing, vertical integration is the key to maximizing profit margins. Rayshape Machinery provides a comprehensive ecosystem that...