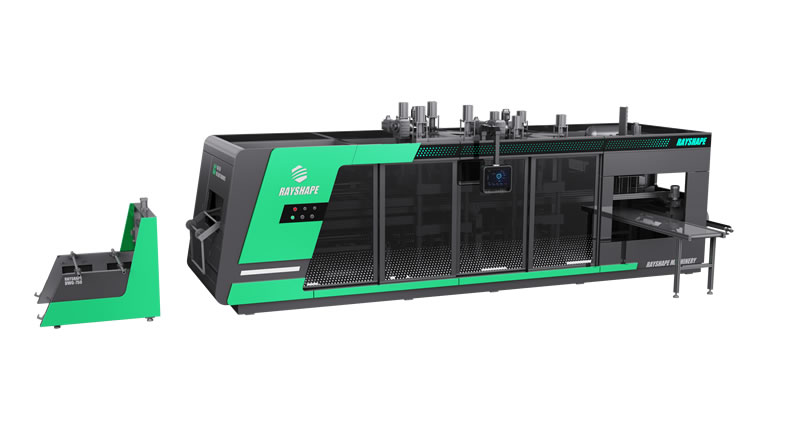

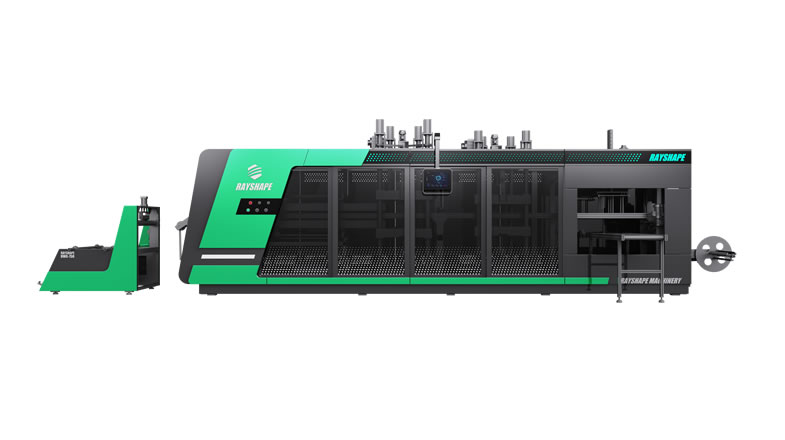

Plastic Thermoforming Machine

Plastic Thermoforming Machine - three station

Fully Automatic Plastic Thermoforming Machine

Plastic Thermoforming Equipment

Precision in Food Packaging: How Rayshape’s Multi-Station Systems Define the Future of Disposable Containers

Meeting the Rigorous Standards of the Food Industry

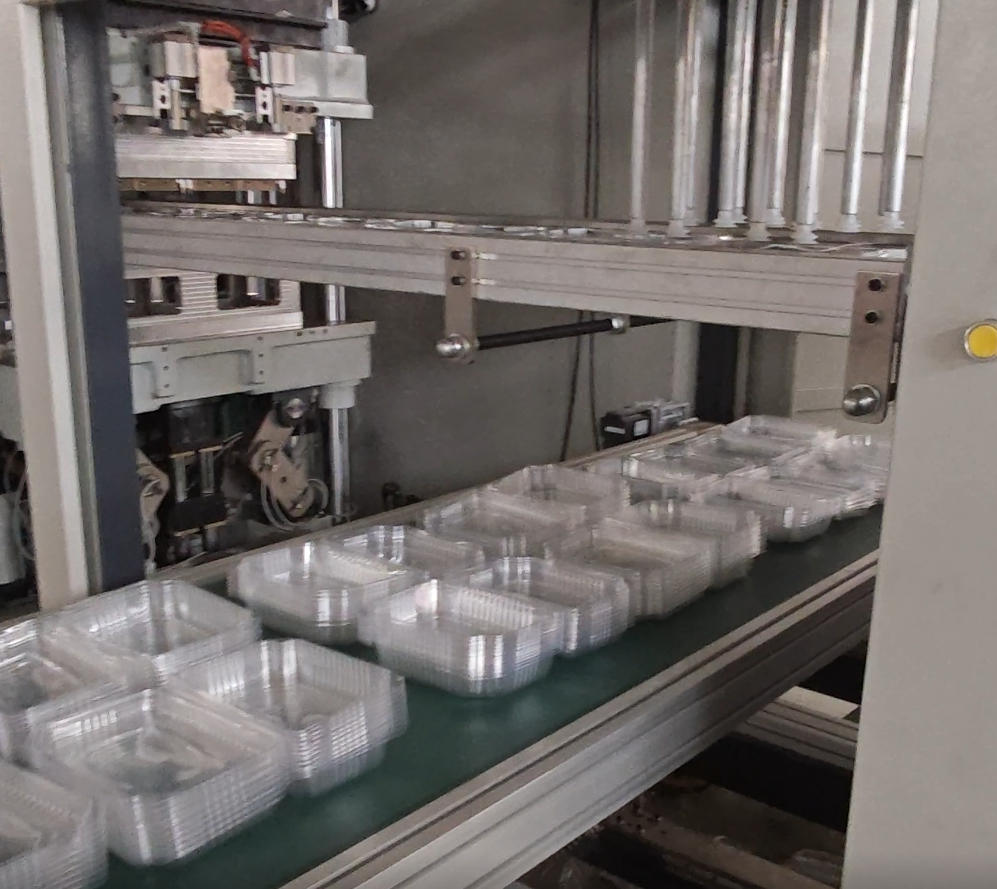

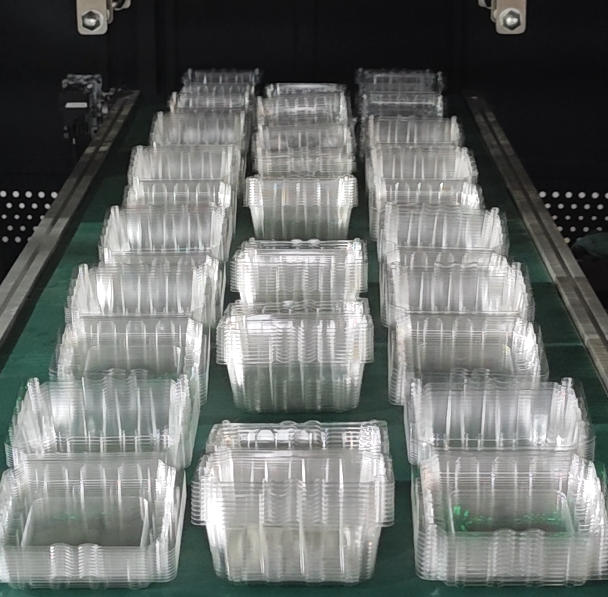

In the food packaging sector, hygiene, consistency, and speed are the three pillars of success. Whether it is an Egg tray making machine application or a high-speed Cup Making Machine line, the equipment must produce containers that are both aesthetically pleasing and structurally sound. Rayshape Machinery has spent years refining its Multi-station Thermoforming Machine to meet these exact requirements. Our machines are the backbone of production facilities that supply the world's supermarkets with plastic meal boxes, fruit containers, and beverage lids.

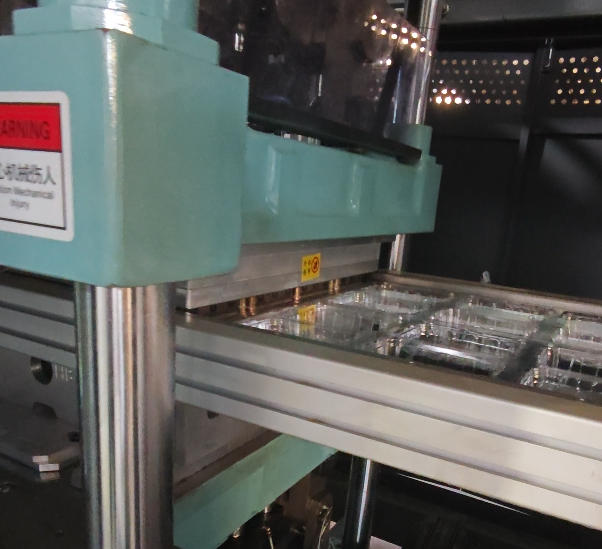

The 4-Station Advantage: Integrated Punching and Cutting

For many food-grade containers, such as those used in the produce industry, ventilation is key. A Fruit box making machine must not only form the box but also punch air holes to ensure the freshness of the contents. Rayshape’s four-station configuration is a game-changer in this regard. While the standard three stations (forming, cutting, stacking) are sufficient for basic trays, the fourth station adds an integrated punching function.

This integration is vital for reducing labor costs and ensuring precision. When punching is handled in a separate machine, the risk of misalignment increases, leading to higher scrap rates. By performing forming and punching in one continuous sequence within the Fully Automatic Thermoforming Machine, Rayshape guarantees that every hole is perfectly centered, and every edge is clean. This level of precision is what separates high-end retail packaging from generic, low-quality alternatives.

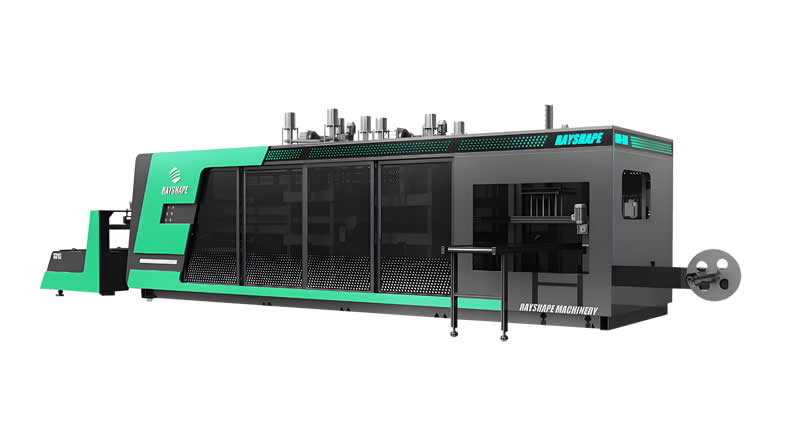

Scale and Capacity: Maximizing the Plate Surface

Production volume is a direct result of surface area and speed. Rayshape offers three versatile forming plate sizes: 650 * 450, 730 * 610, and 730 * 800. Choosing the right plate size is a strategic decision for a manufacturer. For instance, our $730 \times 800$ plate allows for a significantly higher number of mold cavities compared to smaller models. In a high-speed Bowl Making Machine setup, this larger surface area means more bowls per cycle. When combined with our rapid cycle times—influenced by our advanced cooling systems—the total daily output can reach hundreds of thousands of units, allowing our clients to dominate their respective markets.

Blister Machine Applications and Beyond

Beyond food containers, Rayshape’s technology extends into the medical and consumer electronics sectors through our high-performance Blister Machine capabilities. Blister packaging requires a perfect seal and high clarity to showcase the product inside. Our positive and negative pressure forming technology ensures that the plastic sheet adheres perfectly to the mold, capturing even the most intricate details. This versatility allows a single Rayshape machine to serve multiple industries, providing a high return on investment (ROI) for our partners.

The Rayshape Commitment to Service

Wenzhou Rayshape Machinery Co., Ltd. is not just a manufacturer; we are a partner in our clients' growth. Our after-sales service capabilities are backed by the financial and operational strength of Elemotion Holdings. From our headquarters in Pingyang County, we provide global support, ensuring that every Plastic Thermoforming Machine we sell operates at its maximum potential. We believe in the spirit of diligence and continuous improvement, constantly innovating to ensure that our food packaging solutions remain the most reliable in the world.

Plastic Thermoforming Machine Video

Plastic Thermoforming Machine News

Engineering Precision: Understanding the Mechanics of Rayshape Multi-station Thermoforming Machines

Introduction Precision engineering is the backbone of the plastic packaging industry. To produce a perfect Fruit box making machine output or a high-quality Cup Making Machine product, every millim...

The Green Revolution in Plastic Packaging: Material Versatility and Sustainability with Rayshape Machinery

The Global Shift in Packaging Dynamics The global packaging industry is undergoing a monumental shift. With increasing environmental regulations and a growing consumer preference for sustainable op...

The Digital Transformation of Thermoforming: Why Rayshape Control System is a Manufacturer Greatest Asset

The Evolution from Mechanical to Digital Intelligence The era of the "manual" factory is over. In today’s competitive landscape, the difference between profit and loss often comes down to how quick...

RAYSHAPE Plastic Thermoforming Machine

The Plastic Thermoforming Machine, often recognized as a multi-station thermoforming machine, represents a significant leap forward in manufacturing technology. Developed specifically to address the c...

The Revolution of Automation in Modern Packaging: A Deep Dive into Rayshape Machinery’s Fully Automatic Thermoforming Solutions

Introduction In the rapidly evolving landscape of global manufacturing, the demand for efficiency, precision, and cost-effectiveness has never been higher. As industries shift toward sustainable an...

From Sheet to Shelf: The Integrated Production Power of Plastic Sheet Extruders and Thermoforming Lines

Introduction In the competitive world of disposable container manufacturing, vertical integration is the key to maximizing profit margins. Rayshape Machinery provides a comprehensive ecosystem that...