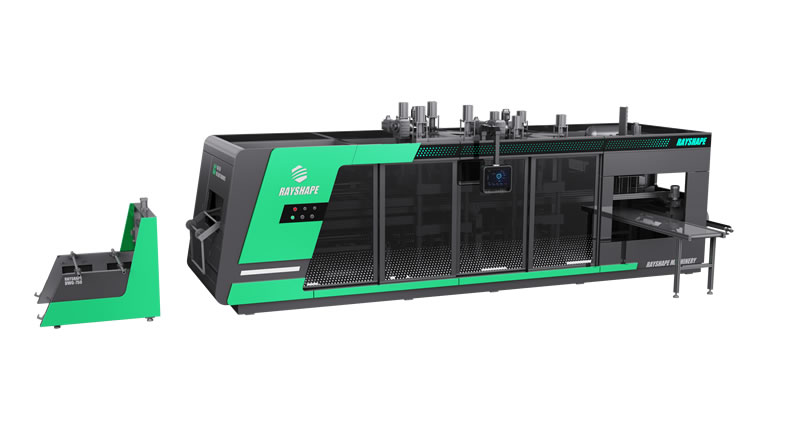

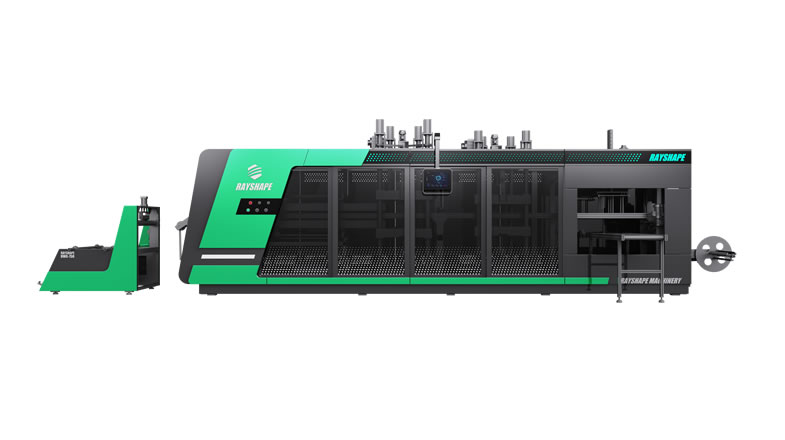

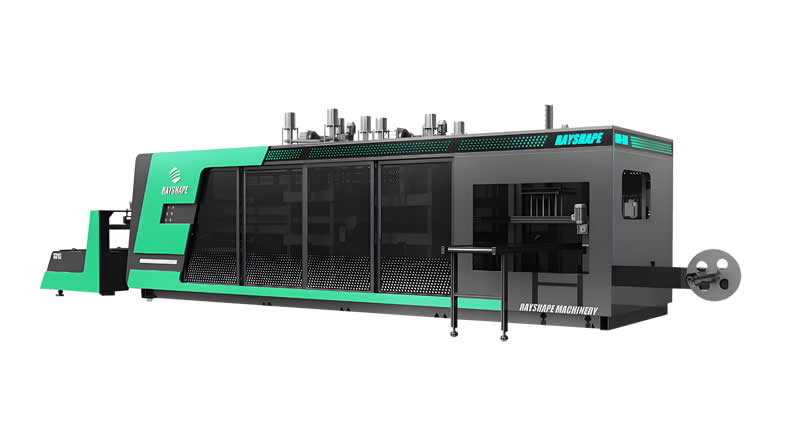

Plastic Thermoforming Machine

Plastic Thermoforming Machine - three station

Fully Automatic Plastic Thermoforming Machine

Plastic Thermoforming Equipment

Engineering Precision: Understanding the Mechanics of Rayshape Multi-station Thermoforming Machines

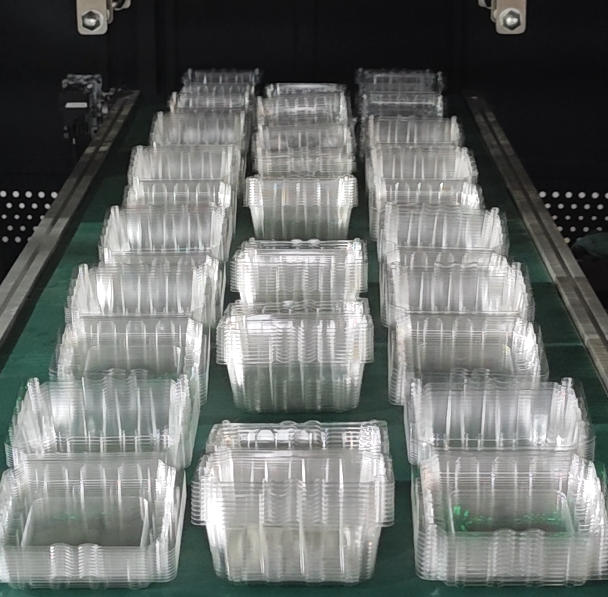

Introduction Precision engineering is the backbone of the plastic packaging industry. To produce a perfect Fruit box making machine output or a high-quality Cup Making Machine product, every millimeter of the forming process must be controlled. Rayshape Machinery has mastered this art through its specialized Multi-station Thermoforming Machine series. These machines represent a significant leap forward in manufacturing technology, specifically engineered to provide stable, reliable, and high-speed output for global markets.

The Importance of Plate Sizes and Cavity Optimization At Rayshape, we understand that "one size does not fit all." The capacity of a Plastic Thermoforming Machine is directly correlated to the size of its forming plate. We offer three standard versatile sizes to meet different production scales:

-

650 * 450 mm: Ideal for smaller, high-precision components or startup operations.

-

730 * 610 mm: The "sweet spot" for many mid-sized containers and egg trays.

-

730 * 800 mm: A heavy-duty configuration designed for maximum cavity count and massive output.

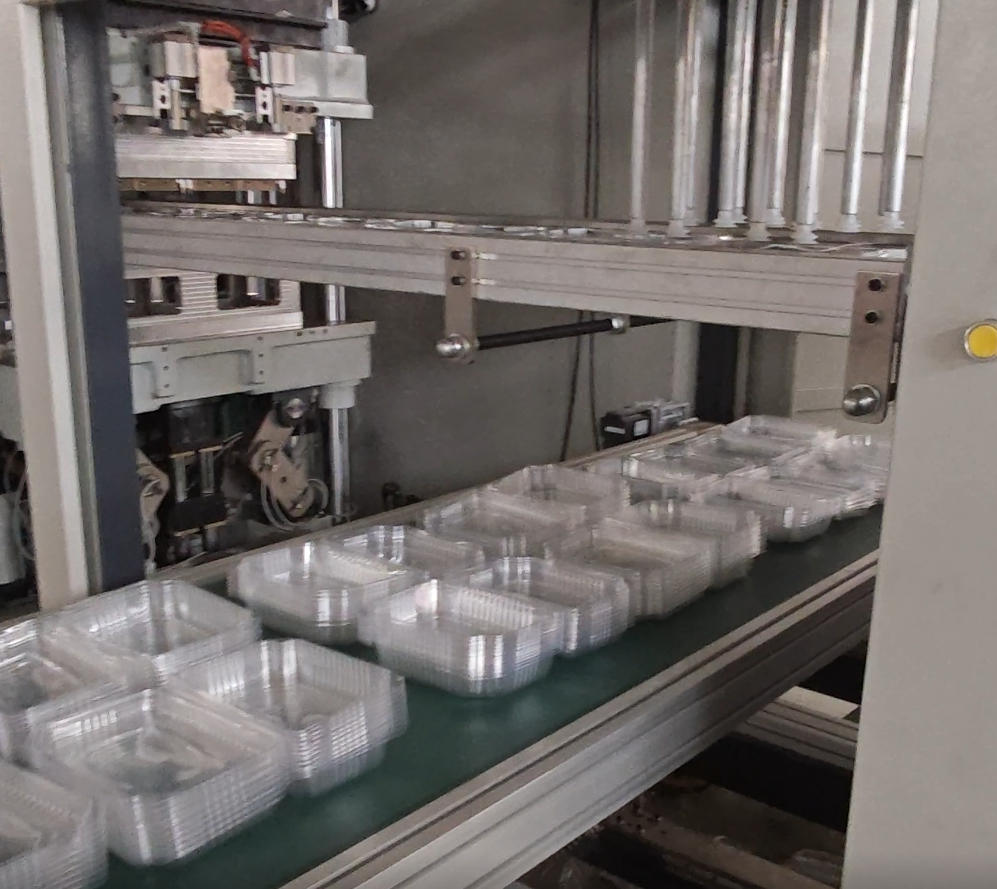

A larger plate allows for more mold cavities. For instance, in Cup Making Machine applications, a larger plate might allow for a 40-cavity mold versus a 20-cavity mold on a smaller machine, effectively doubling production without doubling the energy or labor costs. This scalability is why Rayshape is a preferred partner for industrial-scale packaging providers.

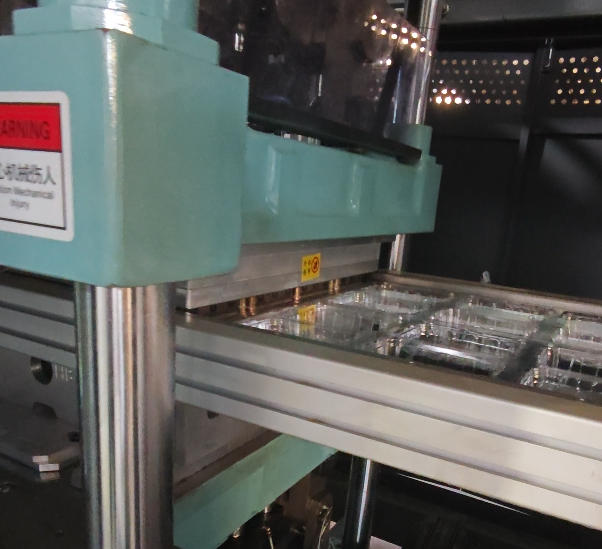

The Four-Station Advantage While many manufacturers offer basic three-station machines (forming, cutting, stacking), Rayshape’s four-station Fully Automatic Thermoforming Machine includes a dedicated punching station. This is critical for products that require internal holes or specialized venting, such as strawberry containers or specialized electronics packaging. By integrating this into the main machine cycle, we ensure perfect alignment between the formed shape and the punched hole, reducing scrap rates and enhancing the aesthetic quality of the final product.

Material Flexibility and Processing Dynamics Modern manufacturers must be agile. The same machine used as a Bowl Making Machine today might need to produce Blister Machine packs tomorrow. Rayshape machines are compatible with A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, and PVC.

The physics of thermoforming dictates that actual operating speed is influenced by product depth and sheet thickness. Deeper products require more time for the material to stretch and cool. Rayshape’s control system accounts for these variables, providing the operator with real-time feedback to optimize the heating and cooling cycles. Whether processing a 10mm shallow lid or a 120mm deep fruit box, our machines maintain the structural integrity and wall-thickness consistency required by top-tier retailers.

R&D and After-Sales: The Rayshape Commitment As a subsidiary of Elemotion Holdings, Rayshape Machinery benefits from a massive R&D infrastructure. We don’t just sell a machine; we provide a complete production solution. This includes a Plastic Sheet Extruder to create the raw material and the thermoforming unit to shape it. Our after-sales service team ensures that every machine installed worldwide operates at peak efficiency, carrying forward the spirit of diligence and continuous improvement that defines our Wenzhou-based headquarters.

Plastic Thermoforming Machine Video

Plastic Thermoforming Machine News

From Sheet to Shelf: The Integrated Production Power of Plastic Sheet Extruders and Thermoforming Lines

Introduction In the competitive world of disposable container manufacturing, vertical integration is the key to maximizing profit margins. Rayshape Machinery provides a comprehensive ecosystem that...

Precision in Food Packaging: How Rayshape’s Multi-Station Systems Define the Future of Disposable Containers

Meeting the Rigorous Standards of the Food Industry In the food packaging sector, hygiene, consistency, and speed are the three pillars of success. Whether it is an Egg tray making machine ap...

The Digital Transformation of Thermoforming: Why Rayshape Control System is a Manufacturer Greatest Asset

The Evolution from Mechanical to Digital Intelligence The era of the "manual" factory is over. In today’s competitive landscape, the difference between profit and loss often comes down to how quick...

RAYSHAPE Plastic Thermoforming Machine

The Plastic Thermoforming Machine, often recognized as a multi-station thermoforming machine, represents a significant leap forward in manufacturing technology. Developed specifically to address the c...

The Revolution of Automation in Modern Packaging: A Deep Dive into Rayshape Machinery’s Fully Automatic Thermoforming Solutions

Introduction In the rapidly evolving landscape of global manufacturing, the demand for efficiency, precision, and cost-effectiveness has never been higher. As industries shift toward sustainable an...

The Green Revolution in Plastic Packaging: Material Versatility and Sustainability with Rayshape Machinery

The Global Shift in Packaging Dynamics The global packaging industry is undergoing a monumental shift. With increasing environmental regulations and a growing consumer preference for sustainable op...