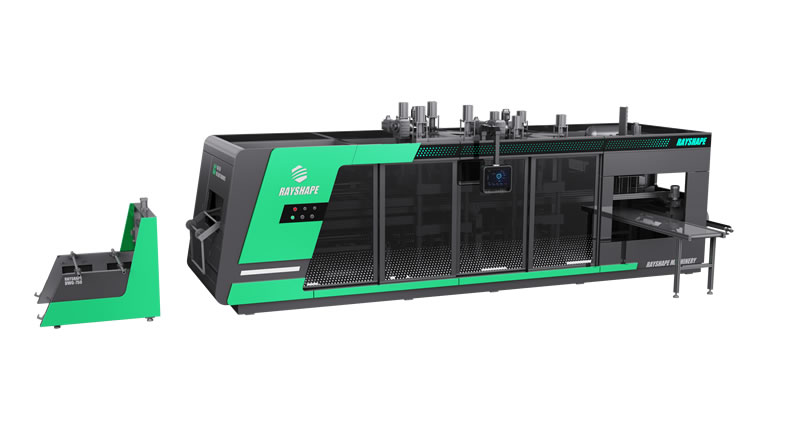

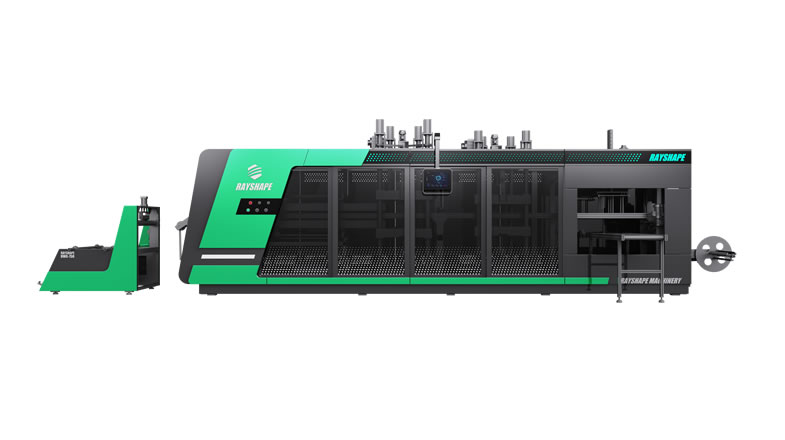

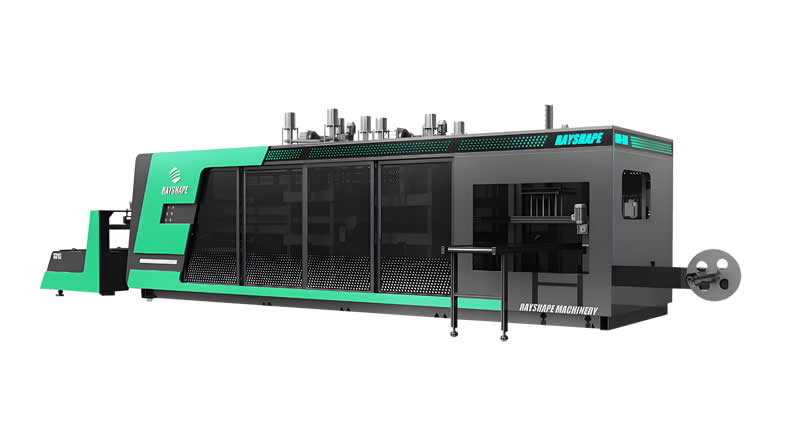

Plastic Thermoforming Machine

Plastic Thermoforming Machine - three station

Fully Automatic Plastic Thermoforming Machine

Plastic Thermoforming Equipment

The Revolution of Automation in Modern Packaging: A Deep Dive into Rayshape Machinery’s Fully Automatic Thermoforming Solutions

Introduction In the rapidly evolving landscape of global manufacturing, the demand for efficiency, precision, and cost-effectiveness has never been higher. As industries shift toward sustainable and high-volume production, the role of the Plastic Thermoforming Machine has become central to the success of packaging enterprises. At the forefront of this industrial shift is Rayshape Machinery, a subsidiary of the prestigious Elemotion Group. Based in the coastal manufacturing hub of Wenzhou, China, Rayshape has dedicated its R&D efforts to perfecting the Fully Automatic Thermoforming Machine, a piece of equipment designed to bridge the gap between high-volume output and low labor consumption.

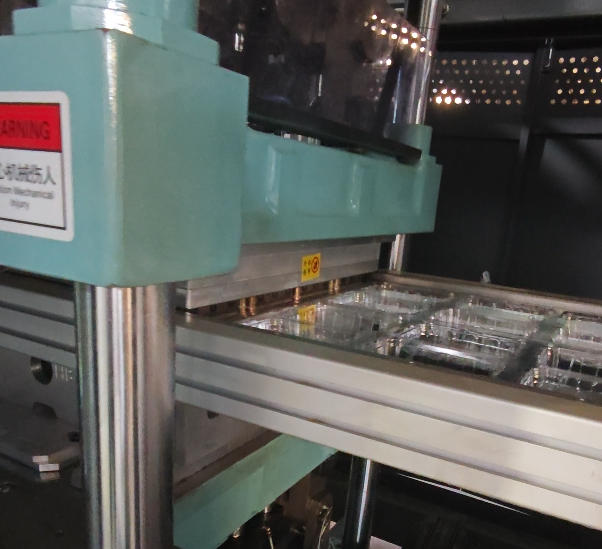

The Shift Toward High-Volume, Low-Consumption Production The primary challenge facing modern packaging manufacturers is the rising cost of manual labor combined with the volatility of energy prices. Traditional forming methods often required multiple operators and frequent manual adjustments, leading to inconsistencies and downtime. Rayshape’s Multi-station Thermoforming Machine addresses these pain points through a sophisticated integration of mechanical and software engineering.

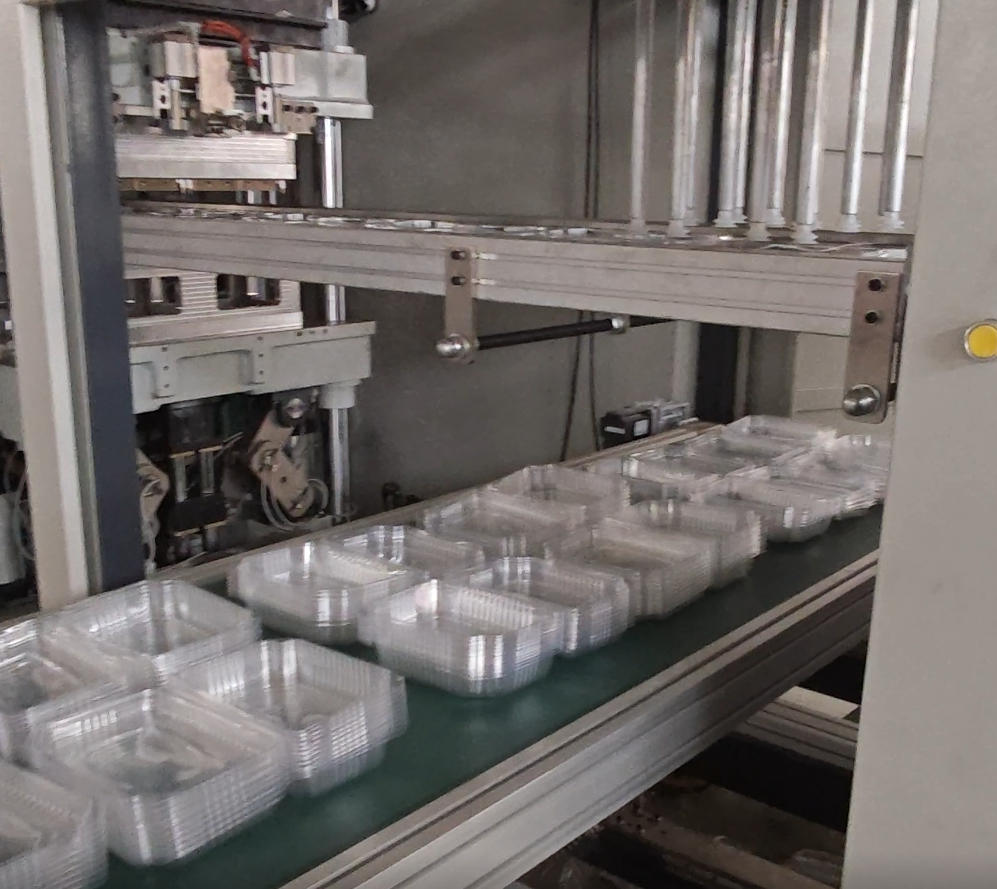

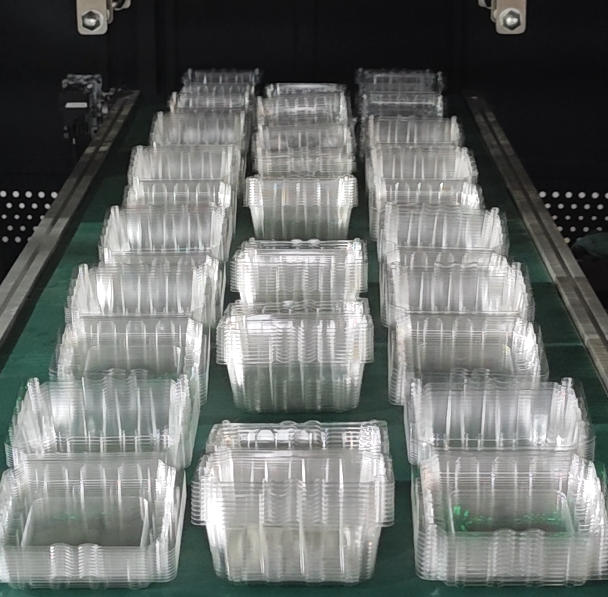

By utilizing a multi-station configuration—typically available in three or four-station setups—our machines allow for forming, punching, cutting, and stacking to occur in one continuous, automated flow. The four-station model is particularly noteworthy for its integrated punching station, which eliminates the need for secondary processing, thereby significantly reducing the footprint of the production line and the number of staff required to oversee the operation.

Technical Excellence: Speed and Versatility One of the defining characteristics of a Rayshape Plastic Thermoforming Machine is its ability to handle a diverse range of materials without sacrificing speed. Our equipment is engineered to process PP, PET, PS, and even newer eco-friendly materials like PLA.

The production metrics are a testament to our engineering prowess. When running PET sheets—a staple for clear food containers—the machine can achieve a maximum operating speed of 45 molds per minute. Even with more challenging materials like PP, which is favored for microwaveable containers due to its heat resistance, the machine maintains a stable speed of up to 30 molds per minute. This high-speed performance ensures that our clients can meet the aggressive deadlines of the modern retail market.

The "Smart" Control System: Future-Oriented Manufacturing Rayshape Machinery recognizes that the complexity of modern molds requires an intelligent interface. Our "future-oriented control system" includes a revolutionary parameter save function. In the past, changing a mold required hours of trial and error by a senior engineer. With the Rayshape system, once an engineer optimizes the parameters for a specific product—such as a fruit box or a cup lid—those settings are saved permanently in the system.

For the operator, resuming production is as simple as clicking 'start.' This automation ensures that the machine executes the stored settings with 100% accuracy every time, regardless of the operator's experience level. This is the hallmark of the Fully Automatic Thermoforming Machine era: removing human error and replacing it with digital precision.

Rayshape’s Corporate Heritage and Vision Located in the Binhai New Area of Pingyang County, Wenzhou, Rayshape Machinery is more than just a manufacturer; it is a legacy of the Elemotion Group. Since Elemotion’s strategic investment in Wuhu Youhe Automation and the subsequent rebranding to Rayshape in 2025, the company has leveraged a seasoned R&D team and solid financial backing to lead the industry. We are committed to the development of high-end, energy-efficient equipment that not only meets current market demands but anticipates the future of the plastic industry.

Plastic Thermoforming Machine Video

Plastic Thermoforming Machine News

From Sheet to Shelf: The Integrated Production Power of Plastic Sheet Extruders and Thermoforming Lines

Introduction In the competitive world of disposable container manufacturing, vertical integration is the key to maximizing profit margins. Rayshape Machinery provides a comprehensive ecosystem that...

Precision in Food Packaging: How Rayshape’s Multi-Station Systems Define the Future of Disposable Containers

Meeting the Rigorous Standards of the Food Industry In the food packaging sector, hygiene, consistency, and speed are the three pillars of success. Whether it is an Egg tray making machine ap...

The Digital Transformation of Thermoforming: Why Rayshape Control System is a Manufacturer Greatest Asset

The Evolution from Mechanical to Digital Intelligence The era of the "manual" factory is over. In today’s competitive landscape, the difference between profit and loss often comes down to how quick...

RAYSHAPE Plastic Thermoforming Machine

The Plastic Thermoforming Machine, often recognized as a multi-station thermoforming machine, represents a significant leap forward in manufacturing technology. Developed specifically to address the c...

Engineering Precision: Understanding the Mechanics of Rayshape Multi-station Thermoforming Machines

Introduction Precision engineering is the backbone of the plastic packaging industry. To produce a perfect Fruit box making machine output or a high-quality Cup Making Machine product, every millim...

The Green Revolution in Plastic Packaging: Material Versatility and Sustainability with Rayshape Machinery

The Global Shift in Packaging Dynamics The global packaging industry is undergoing a monumental shift. With increasing environmental regulations and a growing consumer preference for sustainable op...